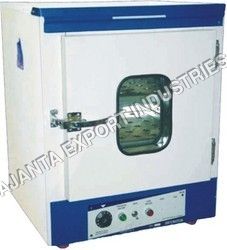

Melting Point Apparatus Microprocessor

Product Details:

- Application Suitable for Boiling & Melting Point, Silicon Oil Bath (Made of High Temp. To ughened Glass)

- Click to View more

Melting Point Apparatus Microprocessor Price And Quantity

- 38000 INR/Piece

- 1 Piece

- 38000.00 - 38500.00 INR/Piece

Melting Point Apparatus Microprocessor Product Specifications

- Suitable for Boiling & Melting Point, Silicon Oil Bath (Made of High Temp. To ughened Glass)

Melting Point Apparatus Microprocessor Trade Information

- Delhi

- Paypal Letter of Credit (L/C) Telegraphic Transfer (T/T)

- 10 Piece Per Week

- 4-5 Days

- Yes

- If order is confirmed we will reimburse the sample cost

- Western Europe Australia Eastern Europe Middle East Central America South America Asia North America Africa

- All India

- FDA, ISO, CE, WHO-GMP

Product Description

Automatic Ramp Rate Proceeding, Auto Gradient Rate of Heating Control. The unit consists of in built magneticstirrer, glare free background illuminator and cylindrical silicon oil bath.The silicon oil bath consists of a plain cylindrical container of corning glasshaving capacity of about 200ml. It is furnished with Teflon cover fitted withspecial type of oil immersion heater, having three small holes for holding thecapillaries, two 6.6mm hole for thermometer (for calibration if required) andTemp. Sensor, another 8mm hole for Test tube, for the determination of boilingpoint of any liquid. A variable speed stirrer is fitted in it. The apparatuscan be used for determination of boiling points, Temp. effect on viscosity/flowpoints and molecular weights by Rasts method with suitable accessories.

Suitable for Dark Colored / all kind or any colored samples.

| Display | LCD 16x2 Linesalphanumeric display |

| Resolution | 0.1 C |

| Temp. Sensor | Grade APT-100, Platinum Sensor |

| Sample Capacity | 3 Samples and one8mm provision for Test Tube for the determination of Boiling Point of anyliquid |

| Application Area | Silicon Oil Bath(Made of High Temp. To ughened Glass) |

| Application | Suitablefor Boiling & Melting Point |

| Melting View | Magnifyingdisplay of melting operation with the help of adjustable magnifying glass,Melting point reading hold on byactivating the HOLD key & reading is protected form power failure RESETis not activated. |

| Heating Control | Microprocessorcontrolled closed loop PID |

| Ramp Rates | 2C to 10C/minute(Selectable Auto-Low-High) |

| Serial Interface | RS-232 to PC |

| Memory | 100 Samples withLocation |

| Power Supply | 230V 10%AC, 50 Hz. |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Heat and Refrigeration System' category

|

AJANTA EXPORT INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese