PCB Prototype Machine with Controller

Product Details:

- Accuracy 0.05 mm

- Features Integrated Controller, Compact Size, High Precision, User-Friendly Interface

- Shape Rectangular

- Temperature Resistance Up to 60C

- Speed Range 4000 to 12000 RPM

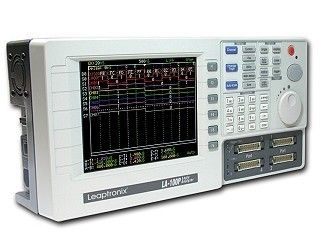

- Control Type Digital Controller

- Display Type LED Display

- Click to View more

PCB Prototype Machine with Controller Price And Quantity

- 1 Piece

- 50000 INR/Piece

PCB Prototype Machine with Controller Product Specifications

- PCB Prototype Machine

- PCB Prototype Machine with Controller

- Laboratory Prototyping, Circuit Board Manufacturing, Educational Projects

- For Laboratory

- Precision Machined Metal Construction

- Metal

- 620 mm x 450 mm x 320 mm

- Up to 60C

- Rectangular

- Integrated Controller, Compact Size, High Precision, User-Friendly Interface

- Prototyping Machine

- 0.05 mm

- AC 220V, 50Hz

- 220 Volt (v)

- LED Display

- Digital Controller

- 4000 to 12000 RPM

- Electric

PCB Prototype Machine with Controller Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 7 Piece Per Day

- 1 Week

- Western Europe, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- All India

Product Description

MarriageAEI-15 is a PCB Prototype Machine with Controller.It has a CNC Router / Engraver,which is easy to operate and competent for elaborate engraving. You can even make a personalized business card with it. The machine includes all the things you need to run the machine, such as the machine body, the control cabinet, the connecting wires, the fixture, damageable spare parts, the specification, software and the blade. It possesses high quality with reasonable price. PCB making machine can finish making a piece of PCB only in a few minutes, which can let your inspiration instant come true.

Features:

· The spindle adopts a 200W hanging mill spindle(with standard configuration) and reaches a extremely high speed.

· The spindle of the machine has very high efficiency with the max. speed of 20000r/min.

· The machine body uses 11-30mm high intensity aluminum alloy board, sturdy, durable with small inertia and great dynamic performance.

· It is nondeformable after being used for a long time. Therefore, the location accuracy is very high.

· X and Z axises are directly connected by compound guide rail, featured by higher intensity and better stability.

· In sign making, the engraving is fine, the bottom surface is smooth and the outline is clear.

· The working theory of 3-axises linkage and adopting imported ball screw create even more accurate location and processing.

· The controller can off-line control the machine. The feeding speed is adjustable, convenient and functional.

· The machine is good at processing small work-peices with multi-speed adjustment, high efficiency and accuracy. The engraver can engrave different kinds of metal or non metal materials, such as iron, copper, aluminium, plastic, wood, etc.

Technical Specification:-

The model number of the product: ST15 include:

1. Machine Body

2 Stepping motor

3 Stepper driver

4 DC power supply

5 Motor cables

6 Mini miller

7 Soft Ware

Worksize: 200mm x 240mm x30mm The size of operation desk: 280×370mm

Processing accuracy: lower than 0.05mm

Resetting accuracy: lower than 0.02mm

Max.speed: 2500mm/min

Command Language: G code

Operating system: WIN2000/XP

Grossweight: 25Kg

Net Weight : 19Kg

Versatile Application & Precise Control

Ideally suited for laboratory prototyping, circuit board manufacturing, and educational projects, this PCB prototype machine delivers high precision and flexibility. The integrated digital controller and touch panel interface streamline workflow, making it accessible for experienced engineers and beginners alike.

Robust Construction & Safety Features

Constructed from durable machined metal and finished in industrial grey, the machine is built for longevity and consistent use. Advanced safety mechanisms like overload protection and an emergency stop ensure safe operation during high-speed prototyping, supporting a stable ambient temperature range from 10C to 40C.

User-Friendly Interface & Flexible Operation

Control and customization are at your fingertips with both manual and automatic operation modes. The LED display and intuitive touch panel allow easy adjustment of parameters, and the machines compact, bench-top shape makes it suitable for laboratories with limited space.

FAQs of PCB Prototype Machine with Controller:

Q: How does the PCB prototype machine support both manual and automatic operation modes?

A: The machine is equipped with a digital controller and user-friendly touch panel, allowing operators to switch seamlessly between manual adjustments for custom prototyping and full automation for streamlined, repetitive tasks.Q: What file formats can be used with this PCB prototype machine?

A: This machine supports industry-standard Gerber and DXF file formats, enabling compatibility with most PCB design software and facilitating straightforward file uploads for prototyping.Q: When is this machine most beneficial within a laboratory or educational environment?

A: The machine is particularly valuable during early-stage product development, research, and teaching. It allows users to rapidly prototype circuit boards, test concepts, and provide hands-on learning experiences without lengthy outsourcing delays.Q: Where should the PCB prototype machine ideally be installed?

A: Designed as a bench-top unit, it fits well in laboratory environments, educational workshops, or compact manufacturing spaces. Its compact dimensions and low noise level ensure minimal disruption and efficient space utilization.Q: What safety features are integrated into the machines design?

A: Safety is prioritized through built-in overload protection and an emergency stop function, which safeguard both the equipment and the operator during intensive use at speeds up to 12,000 RPM.Q: How accurate is the prototyping process with this machine?

A: With a high precision of 0.05 mm and speed range of 4000 to 12000 RPM, users can expect reliably accurate results, making it suitable for intricate PCB designs and advanced educational projects.Q: What are the main benefits of using this PCB prototype machine?

A: Users benefit from rapid turnaround on prototypes, reduced outsourcing costs, simple operation via a digital controller, and a safer, quieter work environment. Its robust build and compatibility with common design files further enhance productivity and flexibility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Electrician Instruments' category

|

AJANTA EXPORT INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese